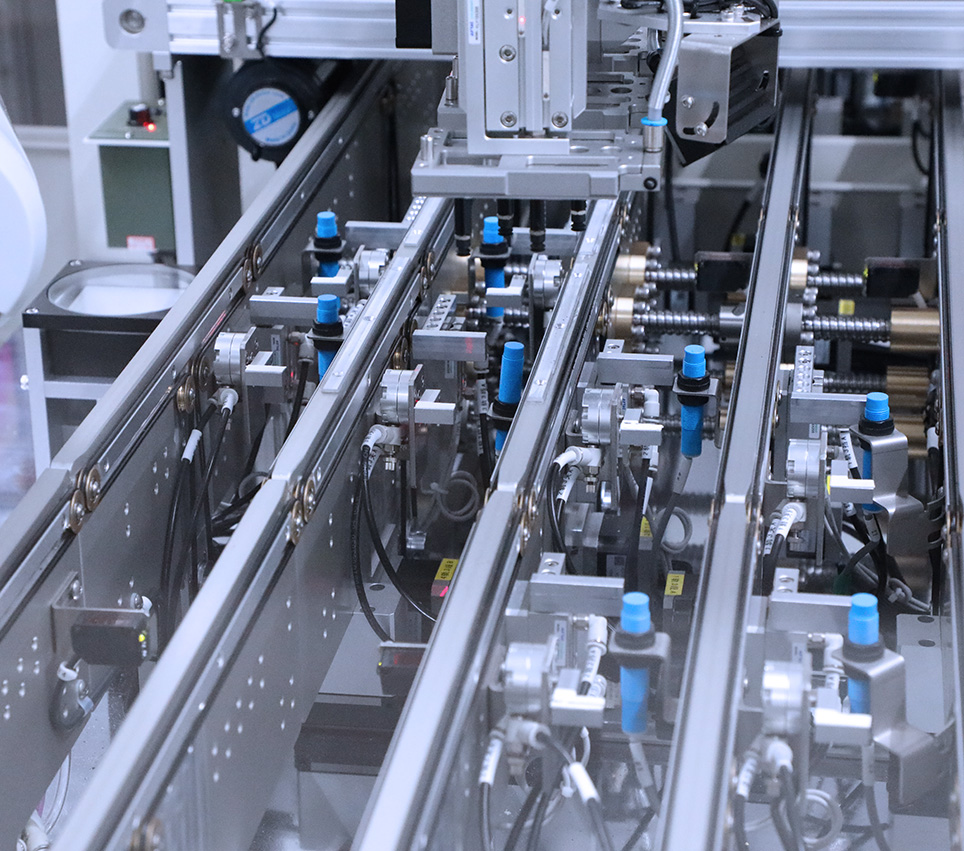

Closed-loop System

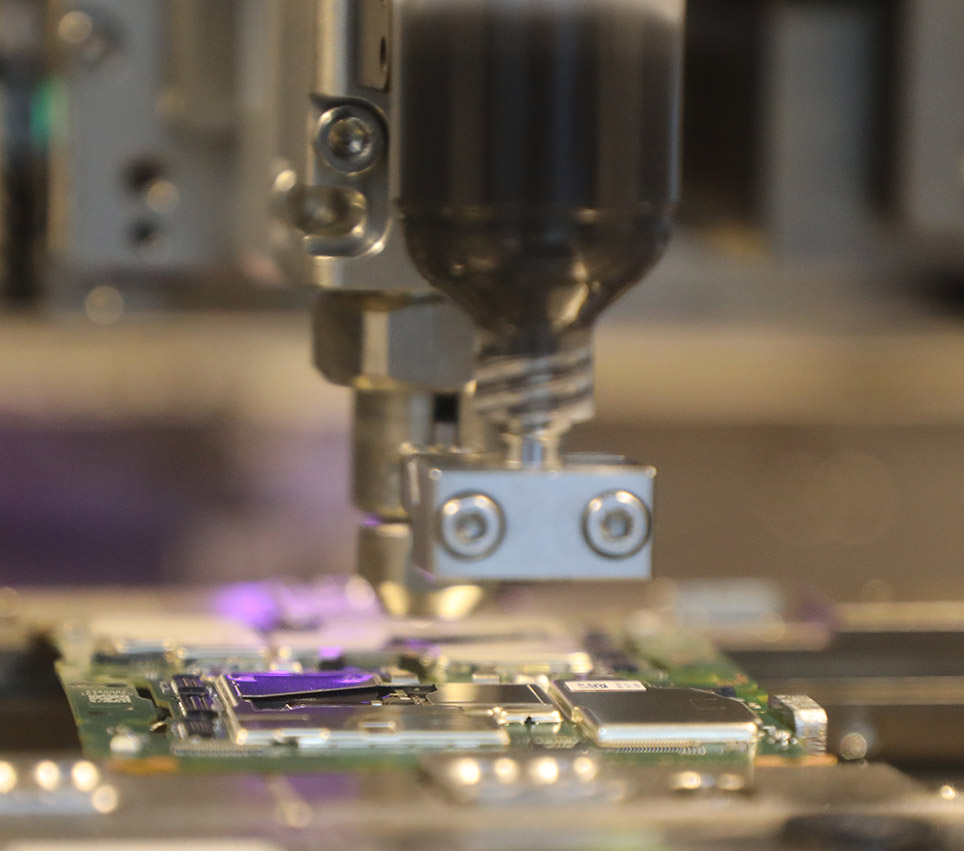

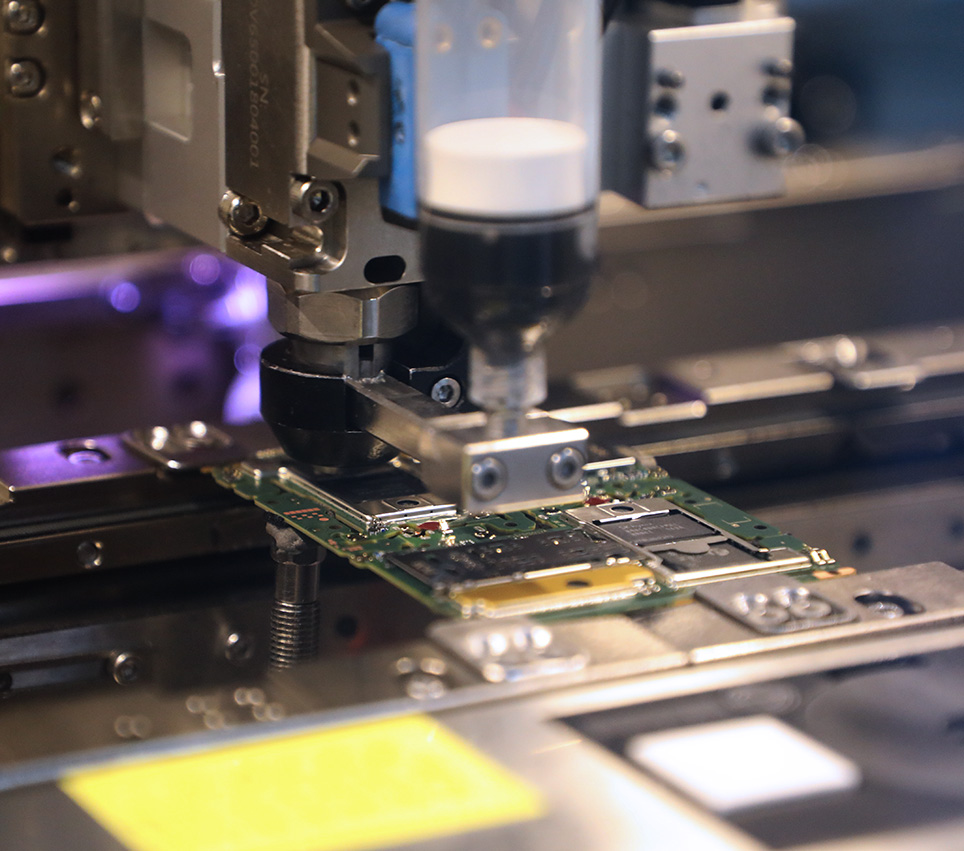

Underfill closed-loop control & spray nozzle

The goal of any electrical or electronic control system is to measure, monitor, and control a process and one way in which we can accurately control the process is by monitoring its output and “feeding” some of it back to compare the actual output with the desired output so as to reduce the error and if disturbed, bring the output of the system back to the original or desired response.

Service detail

eius modi tempora incidunt ut labore et dolore magnam aliquam quaerat voluptatem. Ut enim ad minima veniam

Closed-loop System

The quantity of the output being measured is called the “feedback signal”, and the type of control system which uses feedback signals to both control and adjust itself is called a Closed-loop System.

The Underfill process

Spray nozzles

Underfilling in combination with the best in class spray nozzles enhances the connection strength of electrical contacts and compensates for differences in thermal expansion rates of the two joining materials that could lead to product failure. Underfill is typically used for applications in high shock environments or when consistent reliability is required.