检测中心

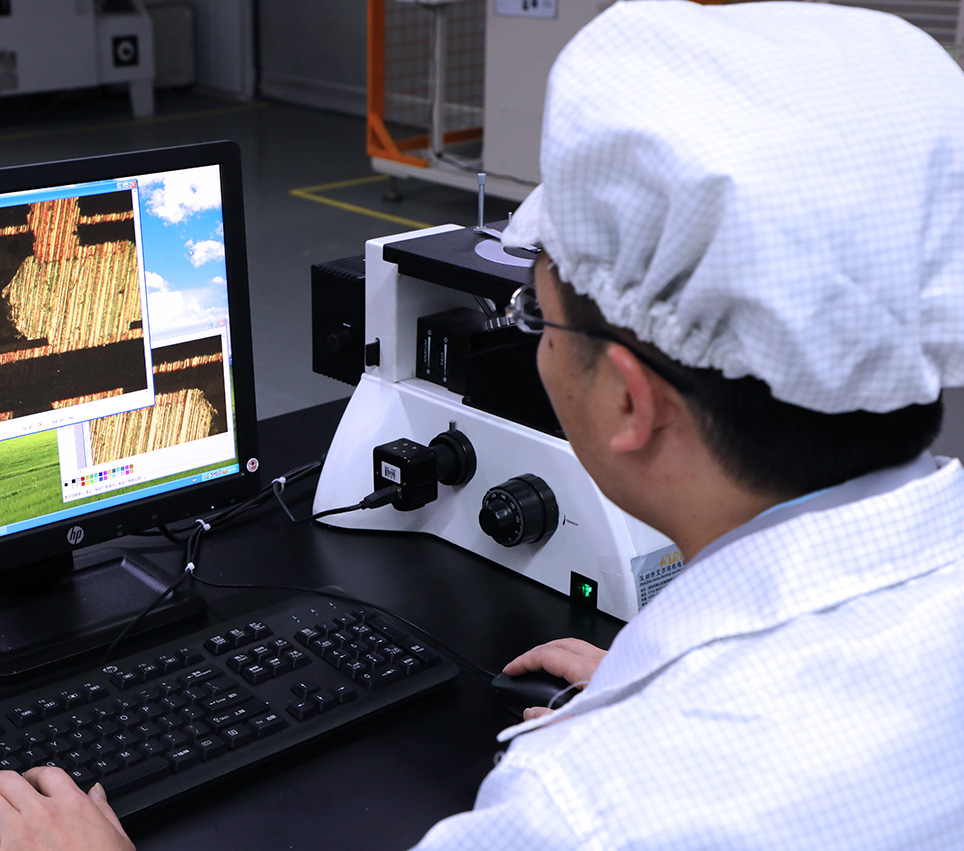

Of course we start with the functional testing of the PCBA, right after it comes out of the SMT line but before it gets assembled into mechanical enclosures. Then we have the Automated Optical Inspection (AOI) and Automated X-Ray Inspection.(AXI) is used in multiple places along the production and assembly line. You might, for example, use AOI after applying solder paste to your PCB but before you place components, to verify correct solder paste placement.

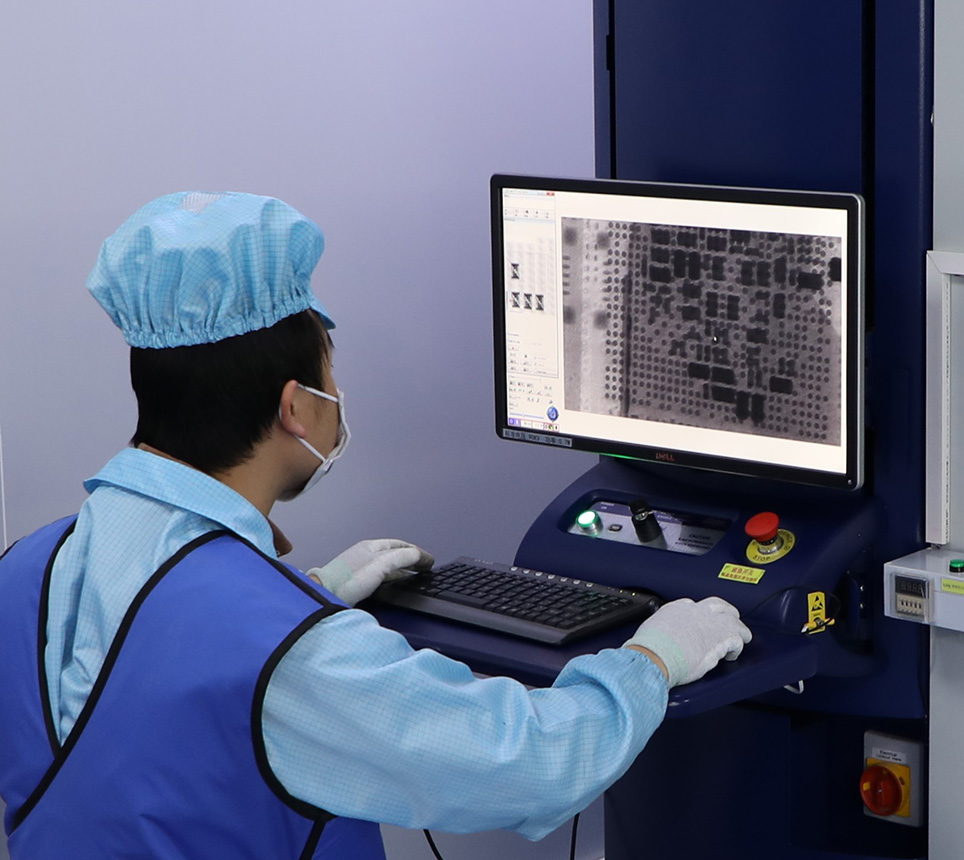

Optical Inspection only catches faults that are visible on the surface of a board, so you won’t be able to see the solder joints underneath those parts to verify good connection to all of the part’s pins. This is where AXI comes into play. AXI offers some great insights into what’s going on in your circuit board. You get to see inside your board, inside the parts on your board, and all of the solder joints, even the hidden ones, to truly verify that all of the connections have been properly made during the assembly process.

Service detail

eius modi tempora incidunt ut labore et dolore magnam aliquam quaerat voluptatem. Ut enim ad minima veniam

自动光学检测